The Ultimate Guide to 6 Types of Shirt Printing Techniques

Do you know why these t-shirts are the most loved and wearable staple? Well, they are considered a unique way of expressing individuality. With the rapid emergence of e-commerce and popular fashion brands entering the t-shirt world, the t-shirt market is projected to reach $51.72B in revenue by 2028.

Do you know why these t-shirts are the most loved and wearable staple? Well, they are considered a unique way of expressing individuality. With the rapid emergence of e-commerce and popular fashion brands entering the t-shirt world, the t-shirt market is projected to reach $51.72B in revenue by 2028.

This comprehensive guide will take you on an exciting journey of the 6 popular shirt printing techniques, empowering you to choose the perfect method for your next project!

Most Common Type Of T-Shirt Printing

To know more about the best type of t-shirt printing techniques, we have listed the major and most used techniques. Back in the days when only traditional printing techniques were used, but now, with the new scope of custom printing, bulk t-shirt printing has insanely become famous. By understanding each of their pros and cons, you will make well-informed decisions on best-suited printing methods according to your needs.

1. Direct-To-Garment Printing (DTG)

.jpg)

Direct-to-garment is the same as printing on paper. This specialized printing method has an inkjet that directly transfers the ink onto the shirt. It excels in intricate designs, colorful patterns, or more detailed work on the fabric. It's important to remember that if you are looking to print on fewer shirts, then they are ideal for this.

How It Works: A digital file of your design is sent to the printer. After fixing the ink and the spray position, the printer sprays ink onto the garment. The ink is then cured with heat to ensure the permanence of the fabric.

Pros

-

Direct-to-garment can print highly complex designs with multi-color or photographic detail.

-

Direct-to-garment printing is ideal for offering a soft feel as its ink seamlessly integrates into the fabric.

-

DTG typically uses water-based ink, which is why it is resistant to washing and can withstand up to more than 60 washes.

Cons

-

DTG can be a price for large orders compared to screen printing.

-

DTG ink blends easily into the cloth, creating a velvety texture.

-

DTG normally employs water-based ink that is resistant to cleaning and can sustain more than 60 washes.

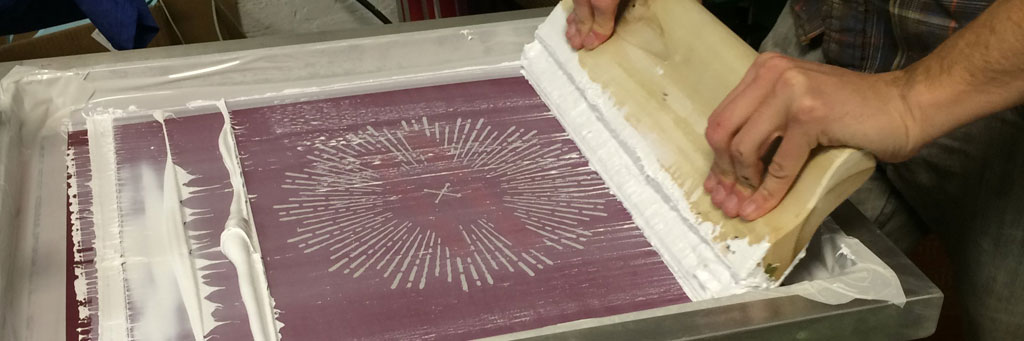

2. Screen Printing

This is one of the popular and effective garment printing types, often known as silk printing. This accurate and tried method uses the stencil to apply ink onto the fabric. This method is ideal for producing vibrant, durable designs on fabric.

However, most people believe that it works best for a few prints but the fact is you can achieve the colorful and intricate design by technically knowing its aspects and experience of artwork separation and halftones.

How It Works: In the first step, the mesh screen is created. Experts suggest nylon and synthetic material be used to make mesh. The design is created by sending the digital file onto the transparent acetate that serves as a stencil. Then, the screen is placed on the shirt and the ink is squeezed across, leaving the design imprinted. Similarly, multiple screens are used for the multicolor print.

Pros

-

Screen printing ink is properly absorbed onto fabric, giving a durable and lasting print.

-

Screen printing is cost-effective for the large print run.

-

Screen printing designs are suitable for various materials or clothing prints.

Cons

-

Screen printing ink is more prone to dispersing and gets messy right after the printing.

-

Screen printing ink and material waste are less environmentally friendly than DTG printing.

-

Less profitable for small-scale or one-off projects.

3. Dye Sublimation Printing

Dye sublimation is also known as all-over printing because you can apply it everywhere. Sublimation printing creates a stunning, full-color design or repeated print even on seams that look like the part of the garment itself. It works best with synthetic fabric like polyester, which brings excellent vibrancy and printing colors.

How It Works: The design of the t-shirt is created in a digital file. Then, the design is printed on special sublimated paper with heat-activated inks. The paper is pressed on the shirt, heated under pressure to the gaseous state, and then cooled and transferred onto the shirt.

Pros

-

It is one of the best quality t-shirts for printing for durable and long-lasting effects, as the print won’t fade or crack.

-

T-shirts prepared with sublimation ink give a soft and breathable feel when worn.

-

Excellent results are achieved on synthetic fabrics like polyester because the dye fully penetrates the fabric.

Cons

-

Dye sublimation doesn’t work with light-coloured synthetic fabric.

-

It is an expensive method compared to other t-shirt printing techniques.

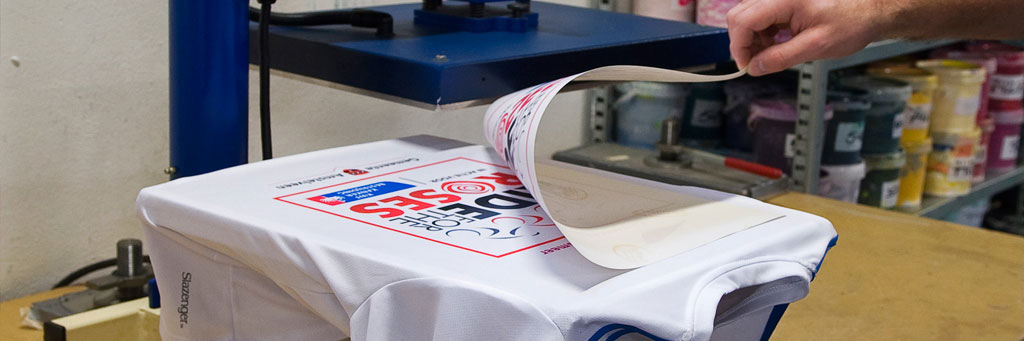

4. Heat Transfer Printing

The heat transfer printing method is different from other types of printing methods because it does not need any dye or special ink for printing. This printing method takes the concept and elevates it to a widely used technique, whether for small business or large-scale production.

This popular printing method lets you print almost any design or image onto the shirt, it's best for those who are aiming to infuse their shirts with a personalized touch.

How It Works: Heat transfer printing involves design creation on a special transfer sheet using a vinyl cutter or digital printing techniques. The design then transfers to the material or the fabric through the application of heat or pressure.

Pros

-

This printing method allows the versatility to print on various fabrics and offers the ideal decoration for t-shirts, hats, tote bags, etc.

-

Heat transfer printing methods are ideal for small batches.

-

Due to the low usage of suppliers, it is considered one of the most environmentally friendly printing methods.

Cons

-

It doesn’t last the same as a traditional screen printing method.

-

Print color options are limited especially if you have a specific color scheme in mind.

5. Airbrushing

Unlike regular printing, airbrushing is a manual t-shirt fabric paint technique that elevates printing to an artistic level. Airbrushing is a technique done with a small, portable brush instrument that sprays a fine mist of paint onto the fabric. It creates a detailed colored design with a photorealistic effect.

However, it is crucial to keep in mind that durable print depends on the correct spray and material, so it is advised to opt for the fabric spray which is used by skilled t-shirt manufacturers in the USA

How It Works: A stencil is created and used for outline and is attached to a t-shirt using a temporary light adhesive on the shirt. Then, the designer mixes the paint and, by using the airbrush tool, sprays a fine mist onto the fabric. Heat is usually applied to ensure the paint adheres permanently.

Pros

-

It is easy to start, bringing unlimited design possibilities and artistic freedom.

-

An inexpensive printing method to print on different types of printed t-shirts.

-

Easily creates detailed, photorealistic graphics and effects.

Cons

-

Proper artistic skills are required to achieve the desired results

-

It can become time-consuming for the intricate and multicolored design.

6. Discharge Printing

Discharge printing is a captivating and inventive method of decorating the fabric through the discharge print, also known as exact printing. This printing method offers a unique approach to printing on dark fabric. It involves using the discharge agent to remove the existing dye on the fabric. This printing method provides a smooth, soft, and subtle look.

How It Works: A stencil is used to block the area of fabric from the discharge agent, such as hydrosulfite or chlorine. The discharge then removes the dye in the designed area. After that, the fabric is washed and dried to remove the remaining discharge agent and reveal the lighter-colored fabric.

Pros

-

Discharge print creates a remarkably soft print for maximum apparel comfort.

-

It is one of the eco-friendly approaches, as it utilizes the existing dye in the fabric.

-

Vibrant and intricate designs emerge even on the dark-colored garment.

Cons

-

Requires a specific discharge agent or careful application to avoid damaging the fabric.

-

Discharge prints are limited to dark-colored fabric, especially black and navy blue.

Conclusion

In conclusion, t-shirt printing methods are extended, and all the creations are done using technology. Many options are available, from classic and durable screen printing to environment-friendly discharge printing. Each of these printing methods entirely depends on the printing needs and specifications. If you're looking to start your t-shirt printing business, then after reading this useful guide, you will surely select the ideal one. So, explore these options and be ready to see your design come to life.