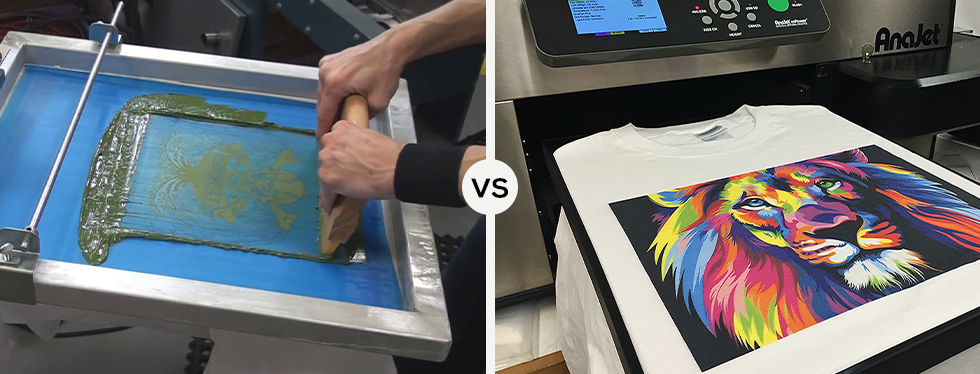

Exploring the Facts Of DTG Vs. Screen Printing Techniques

Everyone is thrilled to have the best print on their shirts in the ever-evolving battle of printing services. Direct-to-garment vs. screen printing: both methods offer unique advantages and disadvantages; you can assess your readiness to venture into the apparel printing world by understanding the limitations and benefits.

Whether planning for a single print on the shirt or looking for several photos for bulk production, you can make or break your business apparel by analyzing the cost and printing needs. This article will guide you through the overall printing comparison and help you discover which printing method suits you, and then you will be ready to delve into the exciting battle on printing titans.

What Is DTG Printing?

DTG printing revolutionized the traditional way of printing. Gone are the days when people used to dye and print with an old machine, but now it is just one click away from doing it with DTG print. DTG printing is formulated to print just on the garment; it uses some aqueous inkjet sprayed directly onto it.

DTG printing is particularly advantageous in numerous designs with diverse color patterns; most importantly, it is best printed on fabric like cotton and can also be printed on different materials, including polyester and much more.

However, DTG offers a digital workflow and easy-to-feel touch, giving the best suggestions to designers, stylists, and individuals looking for high-quality personalized garments.

What is the Process Involved in DTG Printing?

The question often comes to our mind when we discuss what DTG means in printing. All the answers can be found by examining the steps involved in the DTG printing method.

-

First, you need to load the image of the print to the digital graphic program. Proper attention should be given to the design to ensure the image is high quality and matches the color and fabric.

-

The garment must be pre-treated to check whether it is soaked in the ink adhesion. It is manually done by spraying the garment, and then the pre-treated garment is dried using the heat press.

-

Once the garment is dry, it is placed on the DTG printer, which then initiates the printing by sparking tiny droplets.

-

After printing, the garment goes through the curing process to remove all the moisture from the newly printed apparel and ensure it will survive the multiple washes.

Design that Suits It

DTG printing is best suited to several designs and in color, but it is essential to know some rules. Firstly, you must know about the fabric; cotton is best for absorbing and reflecting the proper image. Secondly, you should avoid the transparency of the picture. If it is 100% opaque, then it cannot translate well in the fabric.

Pros Of DTG

DTG is famed for having high quality, numerous designs, and vibrant colors; the best thing about it is eco-friendly and easy to print with only one unit and print many with a single one. This makes DTG an ideal choice with personalized and vibrant designs.

Cons Of DTG

The main disadvantage of DTG printing is its fixed per-unit cost; it costs the same amount whether you are printing a single or dozen. According to the State State Department, the DTG market in America is valued at $2.5 billion.

What Is Screen Printing?

Screen printing is considered a traditional yet highly effective printing method. It is done by mesh stencils, which push the ink over the fabric, as there is a gap in filling that transfers the ink to the garment. Screen printing is popular in terms of the versatility and durability that it brings to the garment.

One of the prominent features of screen printing is that it is easy to run on longer prints compared to the DTG print, which is best for shorter shots. Despite these considerations, it has always taken a core position in the industry because of its ability to produce high-quality and wide range of textile apparel.

What Is The Process Involved In Screen Printing?

Screen printing is a multi-purpose and effective method of transferring ink to the fabric; you will know all the details by looking at the steps.

-

You must begin with the design, which should be transferred to the garment.

-

After that, select the mesh screen by considering each design; if you use multiple colors, multiple Screens are prepared.

-

Then, the prepared Screen is exposed to light, hardening the emulsion around the liquid area.

-

After the emulsion is exposed, it is washed to remove the emulsion behind the mesh stencil.

-

Now place the garment on the flat surface and align the Screen with the desired design.

-

Now, the Screen is lowered and pushes the ink, with the help of squeezing action, transferring the design to the garment.

-

After printing, it is cured to preserve durability by the dried air through the conveyor dryer.

Design that Suits It

Screen printing thrives with bold and solid graphics because it has complex and tiny details. It works best on simple pattern designs and limited color palettes.

Pros of Screen Printing

One of its marking advantages is that it is cost-effective in the long run and has durability on various materials. Its versatility makes it distinguishable, even for larger orders, meaning the more you order, the more cost-effective it becomes.

Cons of Screen Printing

If you want a multi-colored design, screen printing is not a good option, as the silk screen only prints one color through the single mesh.

Which Is Better, DTG or Screen Printing?

In the difference between DTG and screen printing, certain factors should be considered while selecting the one in this battle. The most common things that you need to focus on are.

Is DTG cheaper than screen printing?

If you are choosing the small order, it is relatively cheaper because it doesn't require any setup cost, film positive, or Screen. Furthermore, DTG printing doesn’t require as much manual labor as screen printing.

How Long Does Screen Printing Last On Shirts?

The longevity of screen printing surpasses that of DTG because screen printing isn’t directly applied to the garment, just like DTG. Regarding how long DTG printing lasts, direct spraying onto the garment can lead to less link absorption through the fabric, causing fading on the number of washes.

Is Screen printing durable?

To analyze the DTG vs. screen printing durability, screen printing ensures durability because the ink used makes a deep and strong bond with the fabric, resulting in a print that withstands multiple washes and maintains vibrancy over time.

Here are some additional factors: is DTG better than screen printing?

| Aspects | DTG Printing | Screen Printing |

|---|---|---|

| Durability | Generally good but may vary over 50 wash | Excellent and gives the best garment longevity |

| Wash resistance | Good, but need to take care of multiple washes | Never fades and keeps its originality over frequent washes |

| Cost | Higher for the larger orders due to various ink usage | Lower for the larger order |

| MOQ | None | Required to cover the setup cost |

| Environmental impact | Considered to be eco-friendly | Generate waste due to more setup and color changes |

Conclusion

In conclusion, the insightful examination of the article emphasizes the significance of understanding the DTG vs. screen printing cost and whether DTG printing is of good quality. This gives you a better perspective on the printing battle.

By reading screen printing vs DTG parameters and comparing them, you will better understand the process and type, helping you choose the best. We are here to provide you with high-quality screen printing services, instilling confidence in the excellence of your fashion apparel.